PV-powered supercapacitors

PV-powered supercapacitors – joint demo by PrintoCent members Elcoflex and Ribes Tech

PrintoCent members presented a joint technology demo at LOPE-C in Münich this year 25.-27.2.2024. How did Italian photovoltaic manufacturer Ribes Tech and Finnish, Oulu-based printed electronics contract manufacturer Elcoflex end-up doing an application demo and what is the result? We interviewed Dr. Francesca Scuratti, responsible for Product Development at Ribes Tech and Janne Niva, Head of Operations at Elcoflex.

Francesca explains how it all started. “When we came to know of each other’s activities through Printocent meetings we immediately knew that we had synergies that could be explored and developed. On Ribes Tech’s side, we recognized the high added value that can be provided to the PV (photovoltaic) if an energy storage realized through similar processes is combined with it, opening up to a plethora of new applications that would be hard or impossible to target with the PV alone.”

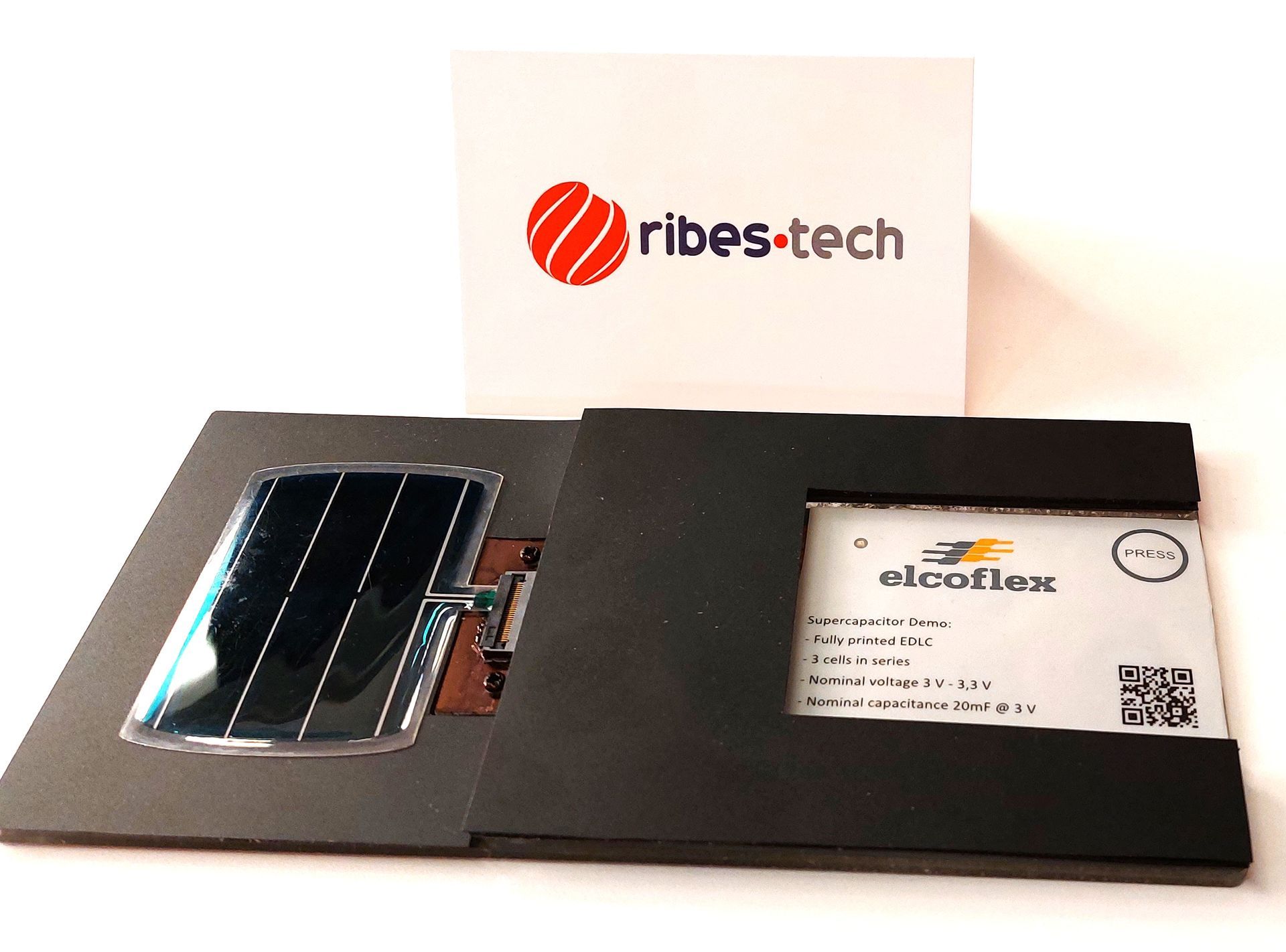

The demo combines printed supercapacitors (SCs)-realized by Elcoflex- and organic photovoltaic (OPV) modules - realized by Ribes Tech. The OPV modules provide power to the SCs without the need of an external power source while the SCs store energy harvested by the OPV from light (outdoor or indoor). The functioning of the system is demonstrated by providing power to a LED, showing the possibility to power battery-free wireless systems that can effortlessly sustain high current density operations.

What are the aimed applications areas for this technology? PV-powered SCs can find use in all applications in which the use of batteries is not feasible because of their cumbersome form factor or because it would not be possible to guarantee their replacement and maintenance: for instance in active flexible RFID tags and data loggers, in distributed IoT nodes, smart wearable sensors, etc.

How was this demo done? Both the OPV and the SC components are printed on plastic substrates and are realized using additive manufacturing roll-to-roll compatible techniques, suitable for high-volume production on flexible substrates. This demo was done combining the elements realized independently on two different substrates. However, the production processes are compatible and we are already discussing how to integrate these components on the same flexible substrate.

For this demo we aimed at realizing a system suitable to power standard electronics at 3V. Elcoflex studied a 3 element SC, powering a LED. Ribes Tech provided a PV panel able to generate the target voltage and supplying enough current in indoor light to charge the SC in short time and keep the supercapacitors charged to sustain periodic activations of the LED.

Any challenges or positive learnings? Elcoflex had already developed a demo of battery-powered SCs, which needed some electronic components to handle the charge of the SCs. When we started discussing we did not know how to integrate the two printed devices without using additional standard electronic components, such as diodes, to interface them. During the development of the PV-powered SC demo we were actually surprised to see that due to the peculiar electrical characteristics of the PV we could actually simplify the electronic design of the finished demo – which is great news and very promising for future industrialization of the system.

And finally, what next? We are currently testing the possibility to laminate the PV and SC on the same substrate; future endeavors will focus on assessing the feasibility of a joint production process. Final goal is to provide a unique device capable to integrate both energy harvesting and storing in a single printed assembly.

This demo is a brilliant example of fruitful collaboration as a result of the PrintoCent cluster activities! Congratulations to both companies!

PrintoCent Founding Members

New Paragraph

All Rights Reserved - Printocent | VTT

Kaitoväylä 1, 90571 Oulu, Finland

Design by JulyPartners.com